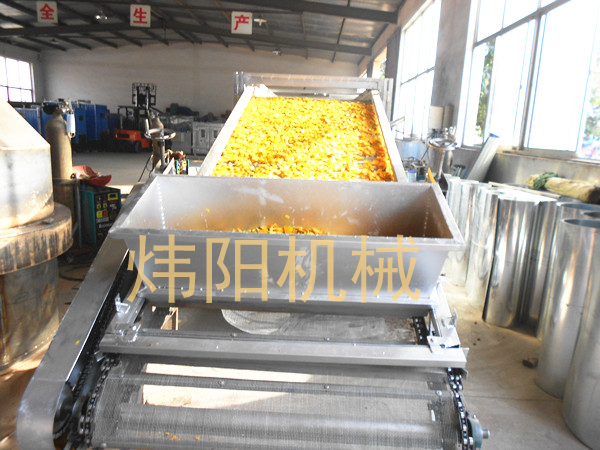

Vegetable mesh belt dryer equipmentComposed of several independent unit segments, each unit segment includes a circulating fan, heating device, separate or shared fresh air intake system, and exhaust system. Therefore, the operating parameters such as the quantity of drying medium, temperature, humidity, and exhaust gas circulation can be independently controlled to ensure the reliability of the work and optimize the operating conditions. The belt dryer is flexible in operation, with wet material feeding and drying processes carried out in a completely sealed box. It has a high degree of automation, good working conditions, and avoids dust leakage. The material to be dried in the belt dryer moves along with the conveyor belt, and the relative position between material particles is relatively fixed, with basically the same drying time. Belt dryers are highly suitable for drying materials that require consistent color changes or uniform moisture content.

2�、 Structure of belt dryerAccording to different combination forms, it can be divided into three types, namely single-stage, multi-stage, and multi-layer belt dryers.

(1) The single-stage belt dryer evenly distributes the dried material from the feeding end to the conveyor belt through the feeding device. The conveyor belt is usually made of perforated stainless steel sheet and is driven by an electric motor through a gearbox. The commonly used drying medium is hot air. The air is drawn in from the outside through an air filter by a circulation machine, heated by a heater, and then blown vertically upward from the lower part of the conveyor belt through a distribution plate. When hot air flows through the material layer, the moisture in the material vaporizes, the air becomes humidified, and the temperature decreases. Part of the humid air is discharged from the box, while the other part is mixed with fresh air at the inlet of the circulating fan for recirculation. After drying, the product is cooled by direct contact with external air or other low-temperature mediaDischarge at the outlet end.

(2)) Multi stage belt dryerThe multi-stage belt dryer is essentially composed of several unitsUp to 4 single-stage belt dryers are connected in series, and their operating principle is the same as that of single-stage belt dryers. In the early stage of drying, materials with high shrinkage, such as certain vegetables, accumulate thick on the conveyor belt, which will cause compaction and affect the flow of the drying medium. At this time, a multi-stage belt dryer can be used to increase the overall production capacity of the unit.

(3) A multi-layer belt dryer consists of multiple single-stage belt dryers connected in series from top to bottom in a sealed drying chamber,High number of layers can reach15 floors, commonly 3-5 floors.The conveying speed of the later layer or layers is lower,Thicken the material layer,This can make most of the drying medium flow throughThe first few thinner layers of material are used to improve the overall drying efficiency. Setting up partitions between layers promotes the directional flow of the drying medium,Make the material dry evenly. The multi-layer belt dryer consists of an insulated chassis, a conveyor chain mesh belt, a chain tensioning device, a dehumidification system, a transmission device, an anti sticking turning conveyor belt, an indirect heating device, and other parts. The lower conveyor belt usually extends 2-3m beyond the outlet of the box, leaving space for workers to pick up deformed and imperfect products during the drying process.

Technical parameters:

| model | DW-1.2-8 | DW-1.2-10 | DW-1.6-8 | DW1.6-10 | DW-2-8 | DW-2-10 |

| Number of units | four | five | four | five | four | five |

| Bandwidth m | one point two | one point two | one point six | one point six | two | two |

| Drying section length | eight | ten | eight | ten | eight | ten |

| Auxiliary material thickness mm | 10-80 |

| Operating temperature ℃ | 60-130 |

| Steam pressure Mpa | 0.2-0.8 |

| Steam consumption kg/h | 120-130 | 150-375 | 150-375 | 170-470 | 180-500 | 225-600 |

| Drying time h | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.25-1.5 | 0.2-1.2 | 0.2-1.5 |

| Dry strength kgHtwoO/h | 60-160 | 80-220 | 75-220 | 95-250 | 100-260 | 120-300 |

Note: The drying strength shown in the table depends on the drying temperature of the material, the thickness of the auxiliary material, and the residence time.

& nbsp;

|

|

|

Onion leaves

| Pepper

| Beans

|

|

|

|

Garlic

| mushrooms

| Yam

|