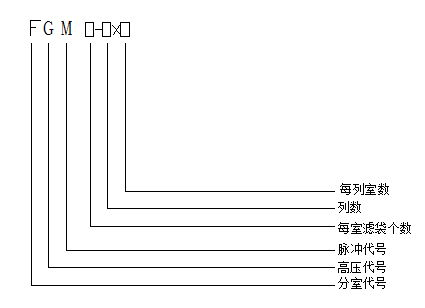

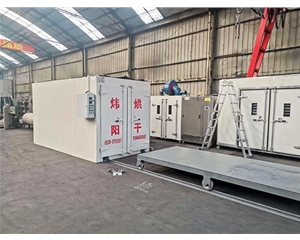

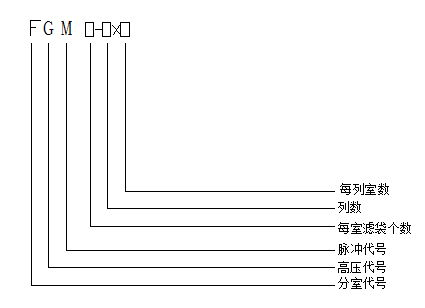

The FGM air box pulse bag filter (plenum pulse) is a dust collector introduced from the American company Fuiler. This type of dust collector has advantages over other types of dust collectors, such as insufficient kinetic energy intensity during chamber blowback and simultaneous filtering and cleaning of dust with pulse blowing. Therefore, it increases the adaptability of bag dust collectors, improves dust collection efficiency, and prolongs the service life of filter bags. On the entire cement production line, not only can it be used as a dust collection equipment for crushers, dryers, coal mills, grate coolers, and cement mills, but its high concentration and rate type can also be directly used as a raw material vertical mill outlet concentration (500g/Nm) gas.

The 0-Spea powder selection machine is used for dust collection of gas with an outlet concentration of 1000g/Nm, and the dust concentration of the collected gas is less than 100g/NM. The filter bag adopts polyester needle punched felt filter material, and the average service life can reach more than two years. At present, the equipment has been widely used, not only quickly selected in cement plants, but also promoted and used in industries such as steel and carbon black.

The gas box pulse dust collector is divided into several box areas, with 32, 64, 96, 128 bags per box. And there is a lift valve driven by a cylinder on each outlet pipe of the box. When the resistance of the dust collector reaches the pre selected value (usually 1500pa), the dust cleaning controller sends a signal. The lift valve of each compartment begins to close to cut off the filtered airflow. Then the solenoid valve of this box is opened (one per box, pressure not less than 0.5MPa), and compressed air flows into the cleaned filter bag to remove the dust. After this action is completed (approximately 10-15 seconds), the lift valve on the outlet pipe will reopen, allowing the box to resume filtering work and follow the above requirements one by one until all dust is cleared.

The pneumatic pulse bag dust collector adopts a separate chamber for dust cleaning. During dust cleaning, it is isolated and rotated box by box to avoid the secondary flying problem of the jet pulse bag dust collector. At the same time, the compressed air cleaning effect is ensured. The entire box design utilizes a compartment structure, and the ash hopper can be extended to the inlet main pipe. The incoming dusty flue gas directly enters the enlarged ash hopper to achieve pre dust collection effect, and can remove horizontal straight pipes that are prone to blockage. So, the segmented pulse bag filter can not only handle dust containing gases of general concentration, but also handle dust containing gases with a concentration of up to 1000g/Nm.

This dust collector uses a full box large pulse valve for back blowing and jet cleaning. When removing the bag, open the top cover and directly remove the filter bag, making maintenance simple and versatile.

| & nbsp; & nbsp; Technical parameters | FGM32-3 | FGM32-4 | FGM32-5 | FGM32-6 | FGM64-4 | FGM64-5 | FGM64-6 | FGM64-7 | FGM64-8 |

| Processing air volume(mthree/h) | five thousand and seven hundred | seven thousand and six hundred | nine thousand and six hundred | eleven thousand five hundred and twenty | fifteen thousand three hundred and sixty | nineteen thousand and two hundred | twenty-three thousand and forty | twenty-six thousand and eight hundred | thirty thousand and seven hundred |

| Filter wind speed(m/min) | 1.0-2.0Select different filtered wind speeds based on different dust emission points, as shown in the tableone) |

| Total filtration area(mtwo) | ninety-three | one hundred and twenty-four | one hundred and fifty-five | one hundred and eighty-six | two hundred and forty-eight | three hundred and ten | three hundred and seventy-two | four hundred and thirty-four | four hundred and ninety-six |

| Filtration area(mtwo) | sixty-two | ninety-three | one hundred and twenty-four | one hundred and fifty-five | one hundred and eighty-six | two hundred and forty-eight | three hundred and ten | two hundred and seventy-two | four hundred and thirty-four |

| Number of dust collector rooms (pcs) | three | four | five | six | four | five | six | seven | eight |

| Total number of filter bags (pieces) | ninety-six | one hundred and twenty-eight | one hundred and sixty | one hundred and ninety-two | two hundred and fifty-six | three hundred and twenty | three hundred and eighty-four | four hundred and forty-eight | five hundred and twelve |

| Dust collector resistance(Pa) | 1440-1740 |

| Imported gas dust concentration(g/m3) | | ≤200 | | | | ≤200 | | | |

| Imported gas dust concentration(g/mthree) | <zero point one |

| Dust collector gas bears negative pressure(Pa) | six thousand |

| Compressed air for dust cleaning | Pressure(Pa) | (5-7)×tenfive |

| Gas consumption(m3/min) | zero point two | zero point two one | zero point three | zero point three five | zero point five | zero point five | zero point eight | one | one |

| Pulse valve (with solenoid valve) | Quantity (piece) | three | four | five | six | four | five | six | seven | eight |

| Specifications(mm) | | twon |

| Lift valve (with cylinder) | Quantity (piece) | three | four | five | six | four | five | six | seven | eight |

| Specifications(mm) | Increase the diameter of the valve plate?460, cylinder diameter?63 | Increase the diameter of the valve plate?500, cylinder diameter?80 |

| Rigid impeller feeder | Discharge portthree hundred×300mm,height450mm,speed30.31r/min,Power of deceleration motor1.1kwProduction volume24mthree/h |

| screw | Specifications | diameter?300Production volume30mthree/h(Filling rate Zeta=0.7 |

| Conveyor | Gear motor | model:XWD2.2-5-1/43,power2.2kw |

| Air conveying chute | If the dust concentration in the imported gas is greater than700g/mthreeThe standard and ash discharge device should use larger sized screw conveyors or air chutes |

| Dust cleaning program controller | The transmission voltage is220v,The controller is supplied by the manufacturer, please refer to the controller manual for detailed information |

| Dust cleaning program controller | Diameter and length Φone hundred and thirty×2450mm,Weight of polyester needle punched felt500g/m2Usage temperatureeighty℃ |

| Insulation layer area | twenty-six point five | twenty-four | forty-one | forty-eight point five | seventy | ninety-four | one hundred and eighteen | one hundred and forty-two | one hundred and sixty-two |

| Total weight of equipment (approximate value, excluding insulation layer)(kg) | two thousand and four hundred | three thousand and four hundred | four thousand and four hundred | five thousand and four hundred | six thousand and nine hundred | eight thousand and three hundred | nine thousand and seven hundred | eleven thousand and one hundred | twelve thousand and five hundred |

| External dimensions | two thousand and fifteen×one thousand nine hundred and eighty

four thousand seven hundred and fifty | two thousand and fifteen×two thousand six hundred and forty

four thousand seven hundred and fifty | two thousand and fifteen×three thousand and three hundred

four thousand nine hundred and fifty | two thousand and fifteen×three thousand nine hundred and sixty

five thousand one hundred and twenty | two thousand one hundred and fifteen×five thousand one hundred and twenty

h:4750 | two thousand one hundred and fifteen×six thousand and four hundred

h:4950 | two thousand one hundred and fifteen×seven thousand six hundred and eighty

h:5210 | two thousand one hundred and fifteen×eight thousand nine hundred and sixty

h:5470 | ten thousand two hundred and forty

h:5770 |

twoThe gas consumption in the table refers to the situation of centralized gas supply in the factory. If a separate air compressor is set up, the gas consumption in the table is multiplied byone point threeCoefficient.

threeThe gross filtration wind speed for processing air volume in the table is1.2m/minCalculated by time, the dust concentration at the user's dust source point is only less than30g/mthree(mark)In the case where the filtered air velocity is also unknown, the selection should be made directly according to the processing air volume indicated in the table.

The data of the equipment can be improved at any time according to the actual situation on site, and the interpretation right belongs to our company.